ÖHLINS AUTOMOTIVE

DFV TECHNOLOGY

ABOUT ÖHLINS DFV

Öhlins DFV (Dual Flow Valve) technology is a groundbreaking innovation in the world of suspension systems. It is a high-performance damping system designed to provide unparalleled control and comfort in a wide range of driving conditions. The DFV technology utilizes a unique and patented valve design that allows for very precise control of the damping forces in the shock absorber speed range that is most critical for handling, traction, and comfort. Utilizing the DFV technology greatly reduces the compromise between handling and comfort that is normally associated with a common single tube damper. The compression and rebound side are tuned individually. Öhlins DFV technology is featured in our entire range of Automotive Road & Track products — whether on the racetrack or the street, this technology delivers exceptional performance and a smoother ride.

HOW DOES IT WORK?

The DFV (Dual Flow Valve) enables tuning the intermediate shock absorber speed range independently from low- and high speed damping. This takes away the compromise between comfort and handling that is associated with common single tube dampers, where the intermediate speed damping can’t be adjusted without affecting low- and/or high speed damping. The Öhlins R&T range uses DFV technology on every single fitment, ideal for drivers who want a versatile upgrade with comfort and agility in one unit.

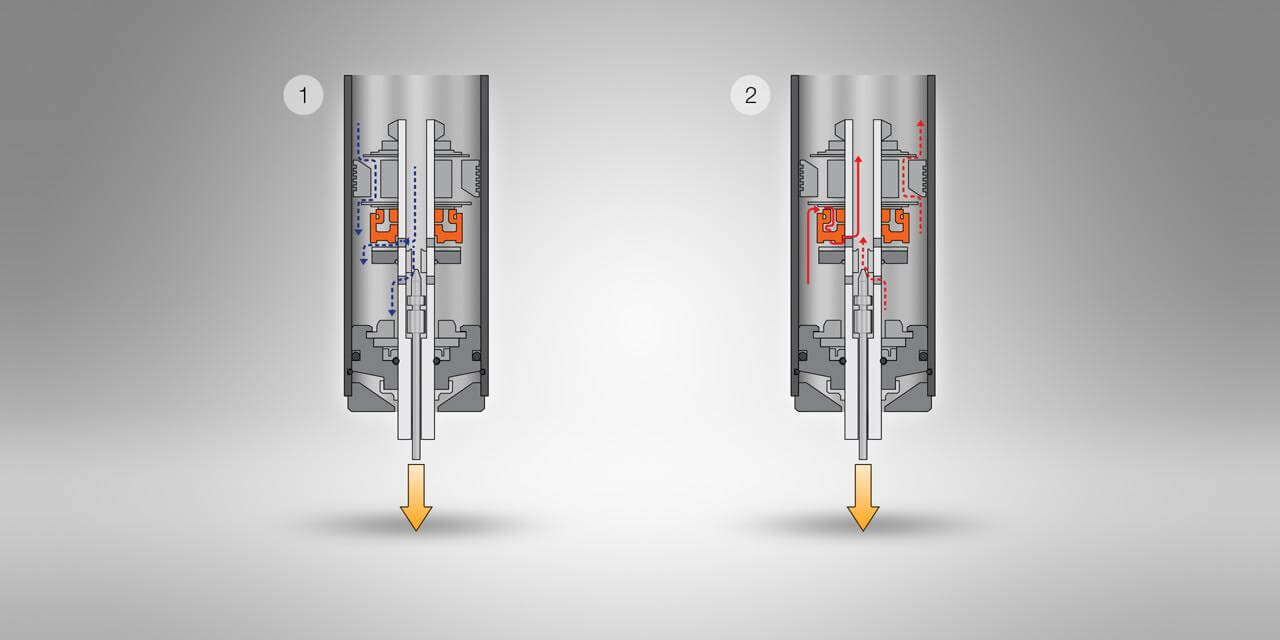

FIGURES 1 AND 2

COMPRESSION & REBOUND

In compression flow (Figure 1) at low shaft speeds, oil flows mostly through the shaft jet bleed (lower dotted arrow). At high shaft speeds, oil flows mostly through the compression ports in the piston (upper dotted arrow). At intermediate shaft speeds, the oil flow can also be regulated by the compression valve in the DFV. During sudden shaft accelerations, oil can also escape through the compression ports in the DFV, further increasing comfort and handling.

In rebound flow (Figure 2) at low shaft speeds, oil flows mostly through the shaft jet bleed (lower dotted arrow). At high shaft speeds, oil flows mostly through the rebound ports in the piston (upper dotted arrow). At intermediate shaft speeds, the oil flow can also be regulated by the rebound valve in the DFV. During sudden shaft accelerations, oil can also escape through the rebound ports in the DFV, maintaining tyre contact with the road.

Because the DFV opens more quickly and easily on minor road imperfections, ride comfort is surprisingly supple and more akin to an OE suspension than an aftermarket coilover set-up. As a matter of fact, a DFV suspension can many times increase comfort over the OE suspension, while at the same time providing the handling, traction, response, and confidence needed for track driving. Over undulating surfaces, the compliancy of the R&T units allows the car to crest bumps and potholes, while remaining stable and in control. Traction is always maintained at its optimal level.

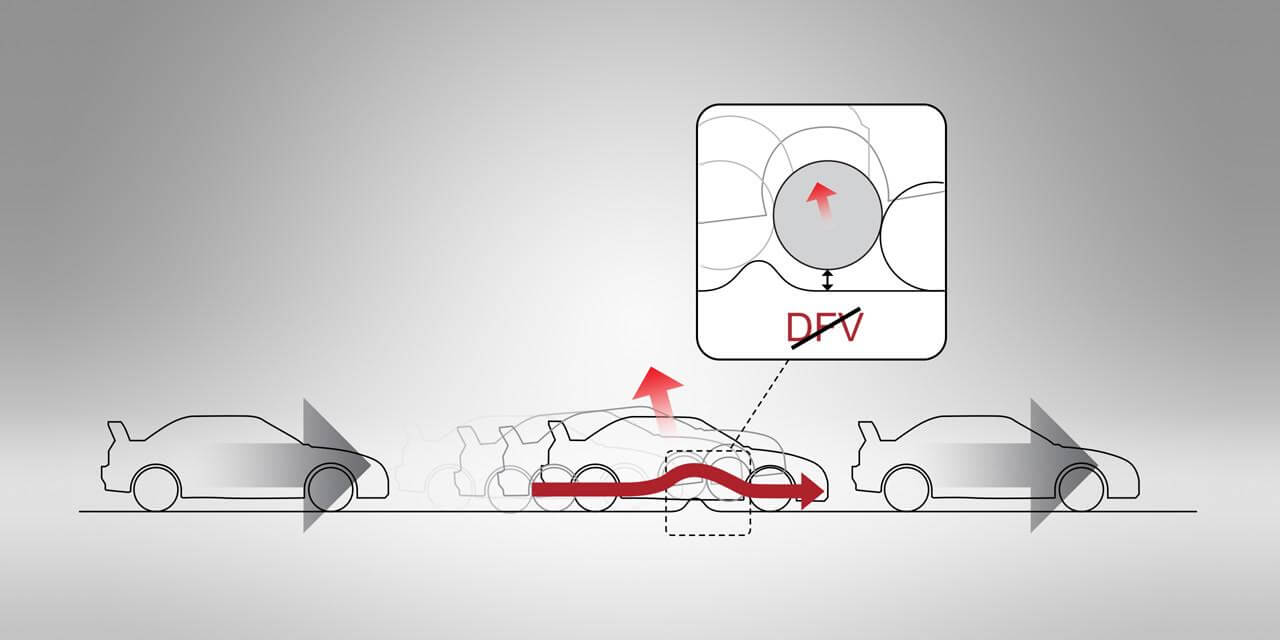

FIGURE 3

WITHOUT DFV

Without DFV, the oil can't flow through the piston quickly enough on the rebound stroke after hitting a bump, making it harder for the tire to stay in contact with the road.

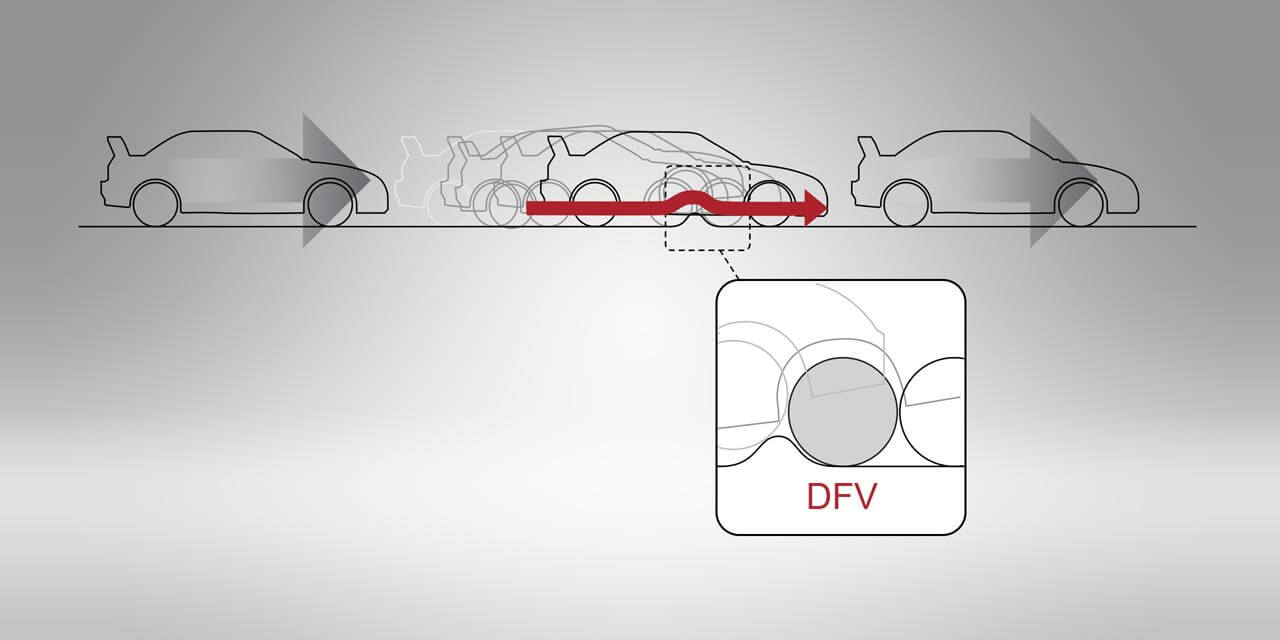

FIGURE 4

WITH DFV

The DFV valve opens, letting the oil flow quicker past the piston on the rebound stroke after hitting a bump, enabling the tire to stay in contact with the road.

When adjusting ride height on coilover units, it’s worth comparing how it’s done. On many designs, height is adjusted by raising or lowering the lower spring platform. This has the effect of compressing or extending the spring, which can limit the suspension travel that may cause bottoming or topping out.

The Öhlins method is to leave the spring seat in its perfect position, and instead adjust the position of the adjuster cup on the threaded body, maintaining the stroke characteristics we took the time to test and perfect. Once it’s set up, the adjuster cup is simply locked off to maintain your exact settings.

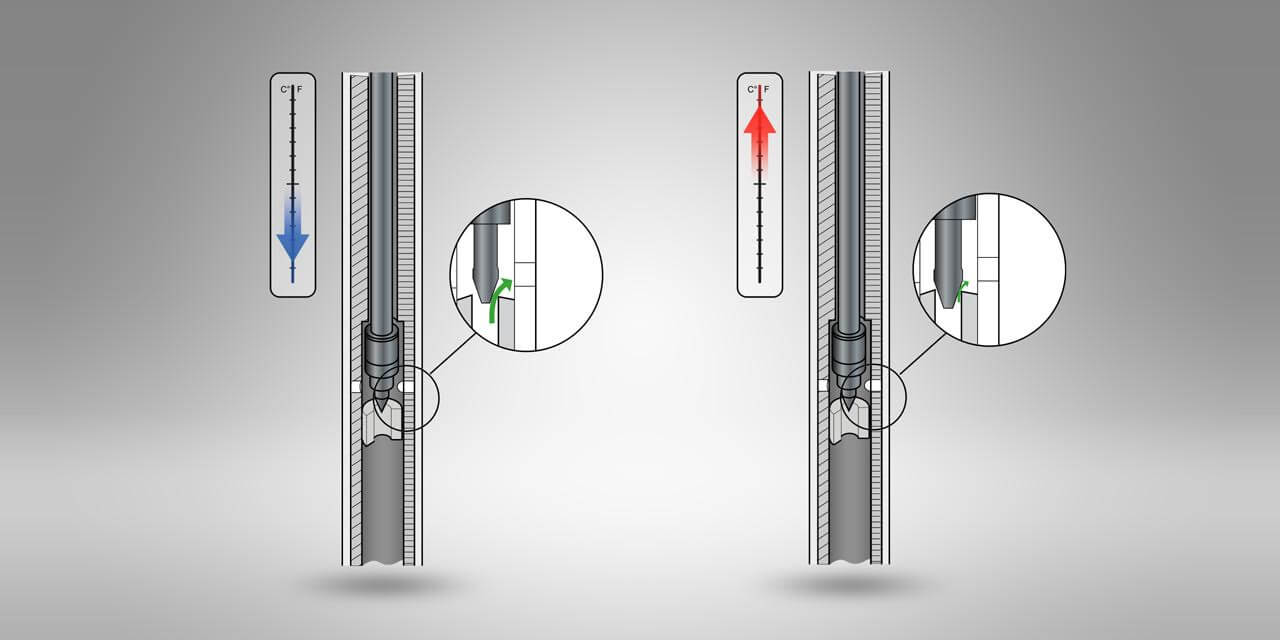

FIGURE 5

THERMAL EXPANSION

Dampers will get hot—that’s one thing that you can be sure of.

As the piston moves within the damper, all the damping work is transformed into heat. Although we can’t stop heat, we can deal with it.

As the heat increases, the viscosity of the damper fluid is decreased, lowering the damping forces, which alters the car’s handling characteristics.

Our unique needle bleed valve system expands with temperature, closing the orifice that the fluid travels through, maintaining a consistent damping rate.

BENEFITS OF DFV

Balances rebound and compression damping characteristics

Improved handling and reduced body roll

Enhanced grip and traction

Versatile technology combines comfort and agility in a single unit

Highly responsive to both major and minor road imperfections

Maintains consistent damping under heat and friction

Enables precise adjustments with a simple setup